11 Jul Glass printed in 3D without sintering

Printing fused silica consisting of pure silicon dioxide in micro- and nanometer-scale structures opens up new possibilities for many applications in optics, photonics and semiconductor technology. But until now, techniques based on conventional sintering have dominated. The temperatures required for sintering silica nanoparticles are above 1100 °C – too hot for direct deposition on semiconductor chips. A research team led by Dr. Jens Bauer from the Institute of Nanotechnology (INT) at the Karlsruhe Institute of Technology (KIT), together with colleagues from the University of California Irvine and the medical technology company Edwards Lifesciences in Irvine, has now developed a new method to produce transparent fused silica of high resolution and excellent mechanical properties at much lower temperatures.

Glass structures without sintering

According to the scientists, the starting material is a hybrid organic-inorganic polymer resin developed in-house. This liquid resin consists of so-called polyhedral oligomeric silsesquioxane molecules (POSS): These are cage-like silica molecules that are provided with organic functional groups. The researchers explain the manufacturing process as follows: Once the fully 3D printed and cross-linked nanostructure is formed, it is heated to a temperature of 650 °C in air. This expels the organic components, and at the same time the inorganic POSS cages bond together to form a continuous micro- or nanostructure of fused silica. The temperature required is only half that of processes based on sintering nanoparticles.

Nanophotonics with visible light

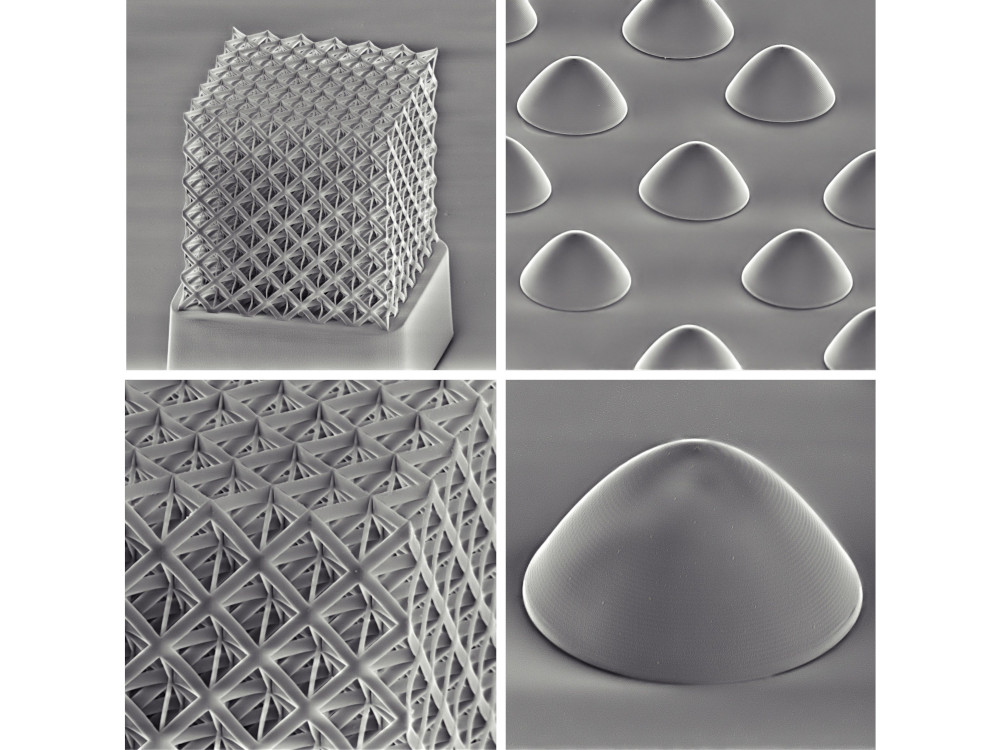

“The lower temperature allows robust, transparent and free-form optical glass structures to be printed directly onto semiconductor chips with the resolution required for visible-light nanophotonics,” Bauer explains. In addition to excellent optical quality, the scientists say, the fused silica produced in this way exhibits outstanding mechanical properties, withstands difficult chemical or thermal conditions and is easy to process. The team from Karlsruhe and Irvine printed many different nanoscale structures with the POSS resin, including photonic crystals made of free-standing 97-nm-thick bars, parabolic microlenses and a multi-lens microlens with nanostructured elements.

Original publication

[J. Bauer, C. Crook, and T. Baldacchini: A sinterless, low-temperature route to 3D print nanoscale optical-grade glass. Science, 2023. DOI: 10.1126/science.abq3037; Abstract unter https://www.science.org/doi/10.1126/science.abq3037]

Information about the excelent cluster 3DMM2O

Source: www.kit.eu

Image: Dr. Jens Bauer, KIT