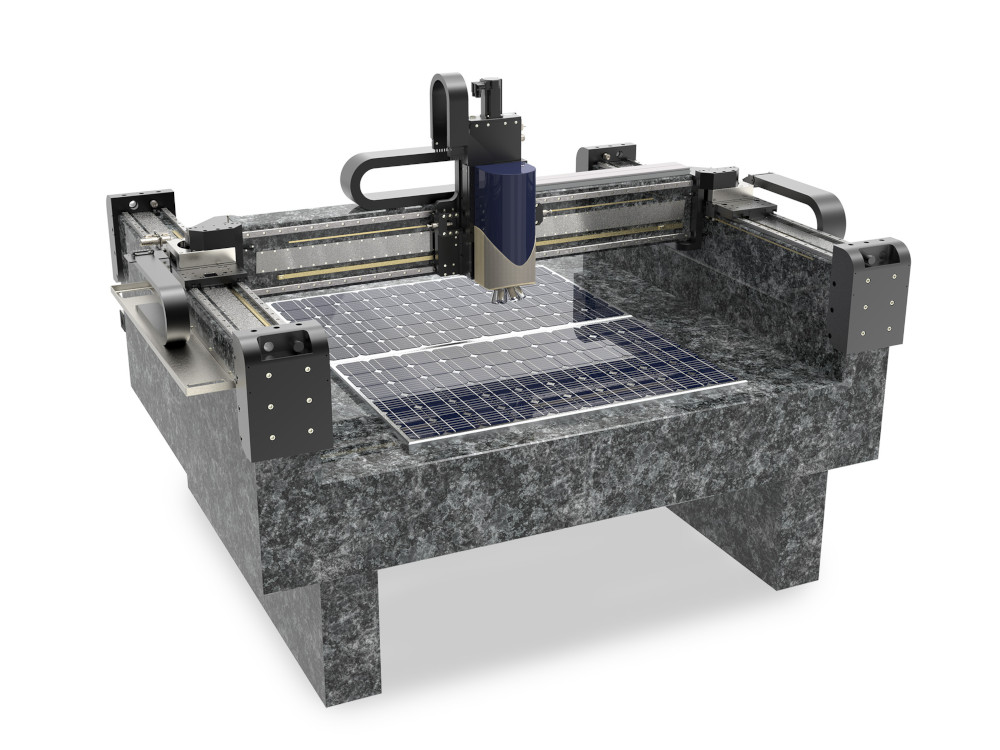

16 Jan Positioning system for inspection and laser applications

The compact gantry system from Steinmeyer Mechatronik allows movements over an area of 1000 x 800 mm2, which can be adapted to the task and the available space. The repeatability is 0.3 µm. The integrated linear motors enable process speeds of up to 500 mm/s in the horizontal XY plane. On the vertical Z axis, the AC servo achieves velocities of up to 200 mm/s. The custom processing head or sensor is mounted on the Z-axis and moves over the carriers on the granite. The traverse is designed for loads up to 10 kg, while the height can vary up to 500 mm depending on the application and component height. For an optimum of motion, the profile rail guides are mounted directly on the granite.

According to the manufacturer, the positioning system is shipped fully fitted with frame and matched vibration isolators, approved dimensions and commissioned, and with integrated safety technology in accordance with the machinery directive. The control system is individually adapted to the customer’s control architecture, and motion-synchronous triggering of customer-specific measurement sensors is possible. The gantry design also allows integration into cycle lines and the lining up of several such gantries.

Additional casing with integrated extraction or housing enables the XYZ system to meet the requirements for cleanroom class ISO 6. Further customer-specific adaptations are said to be possible, including travels, length combination, cabling and motion control. For the inspection of complex geometries, the gantry system is combinable with lifting tables and / or rotary axes.

According to the manufacturer, the gantry system is suitable for inspection systems in semiconductor or optics manufacturing or high-precision and dynamic applications such as laser joining or laser micromachining in medical technology fabrication.

Further information from the manufacturer

Source and image: www.steinmeyer-mechatronik.de/en