16 Jan Additive manufacturing simulated from start to finish

Laser powder bed fusion (LPBF), which is used to manufacture additive components and tools, offers short innovation cycles and high cost-effectiveness. Particularly important for the mechanical properties of an additively manufactured workpiece is the microstructure made of metallic grains. These have certain orientations, sizes and shapes and influence, for example, the elastic modulus of the material or the yield stress – i.e. the load above which the material deforms plastically. Components and workpieces are also frequently made from various metallic alloys: steels, aluminum alloys, titanium alloys in different compositions and mixing ratios. Each alloy material has different properties and forms different microstructures. Until now, the optimum process parameters and materials have been determined experimentally and thus with time-consuming effort.

Different simulation methods combined

Researchers at the Fraunhofer Institute for Mechanics of Materials IWM are now taking a different approach by simulating the entire process chain. Dr. Claas Bierwisch, team leader at Fraunhofer IWM, explains, “In this way, we not only reduce trial-and-error loops, but we can also quickly and effectively evaluate variations in the overall process and eliminate undesirable effects during manufacturing.”

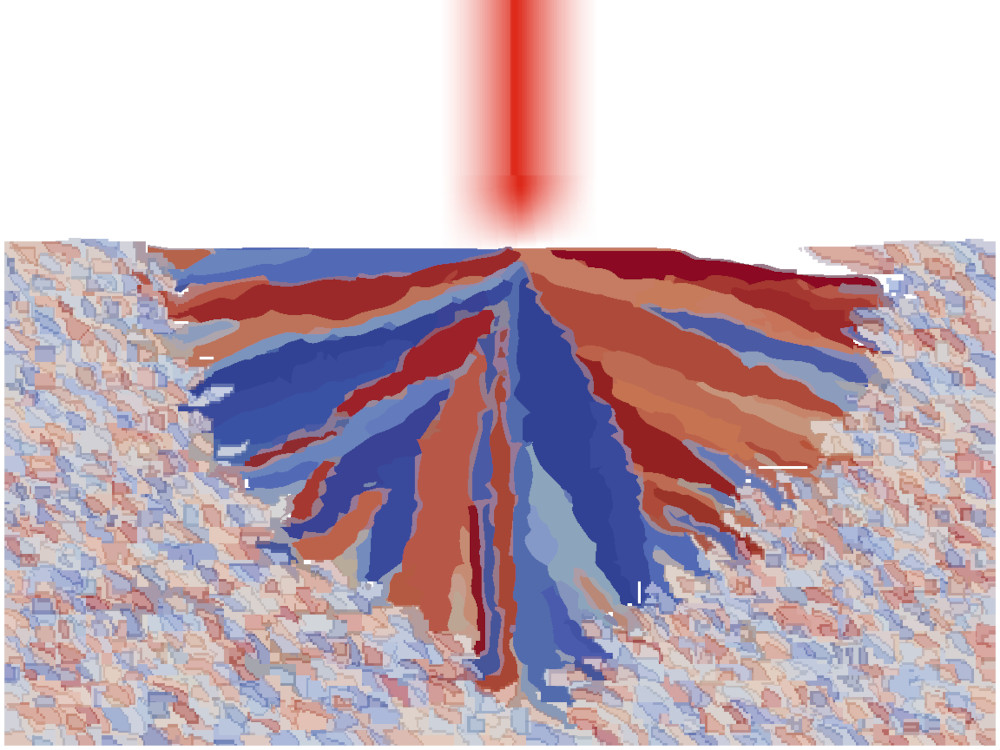

Simulation of a columnar microstructure in the laser melting pool. Image: Fraunhofer IWM

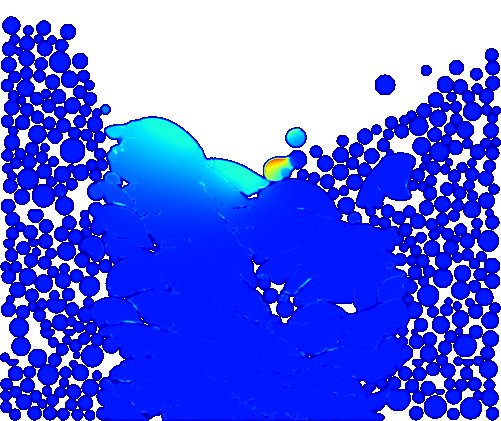

Simulation of the LPBF process with lack-of-fusion defects and residual porosity. Image: Fraunhofer IWM

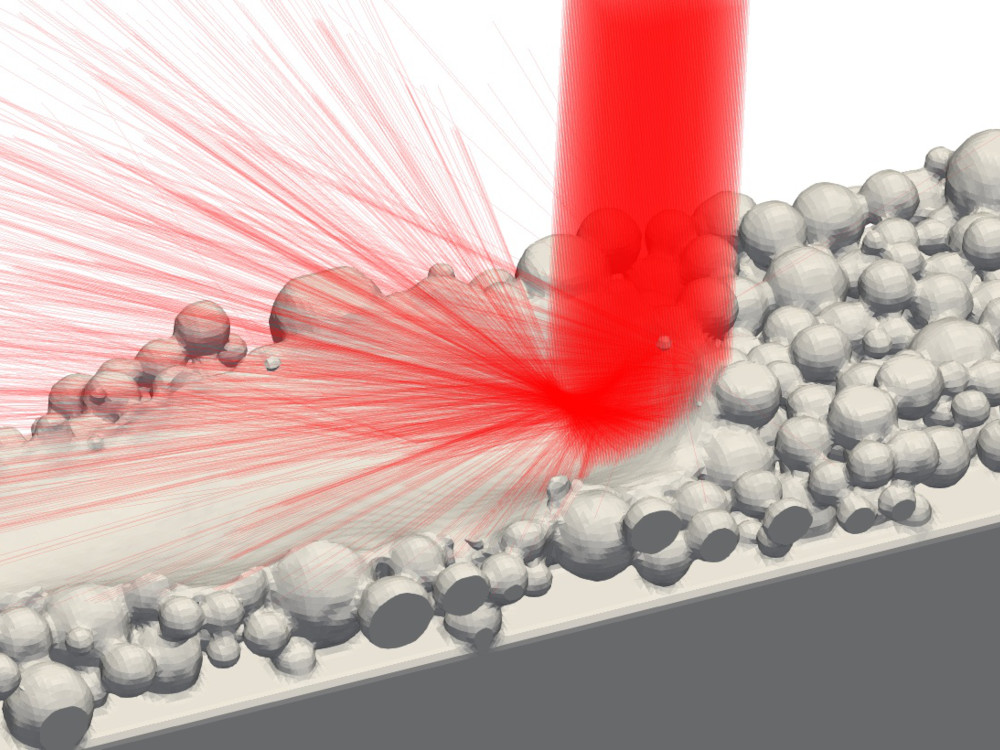

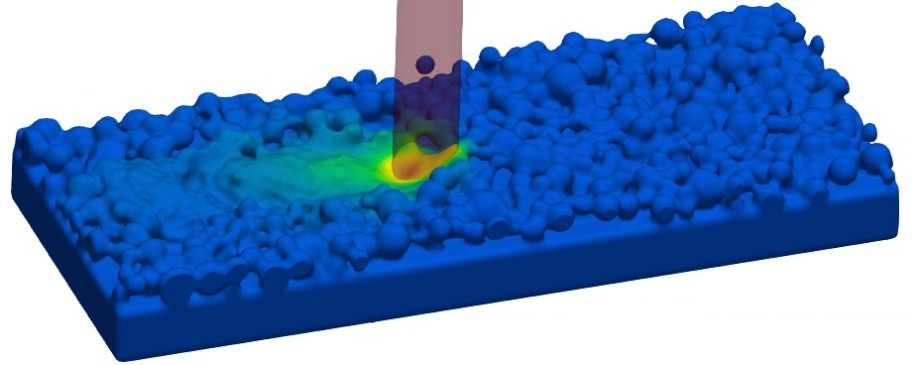

To do this, the researchers combined different simulation methods. Using the discrete element method, they first simulate how the individual powder particles are spread in the build chamber using a special tool called the doctor blade. The subsequent smoothed particle hydrodynamic method simulates the melting of the powder particles – both the laser interaction and heat transport are calculated, as well as the surface tensions that lead to the flow of the melt. Gravity and the recoil pressure that occurs when the material vaporizes are also included in the calculation, the scientists said.

In order to analyze the microstructure, another simulation method was coupled, a so-called cellular automaton, explains Bierwisch. This describes how the metallic grains grow as a function of the temperature gradient. Where the laser hits the powder, temperatures reach up to 3,000 °C – but a few millimeters away, the material is already cool. The laser also moves over the powder bed, in some cases at a velocity of several meters per second. The material is therefore heated up extremely quickly, but then also cools down again within milliseconds. According to the scientists, the final step is finite element simulation: the research team uses it to calculate tensile tests in different directions on a representative volume element of the material to see how the material reacts to these loads.

Simulation of the LPBF process with color-coded temperature field. Image: Fraunhofer IWM

Observing effects live

“While in the experiment you can only examine the final result, in the simulation we can watch live what happens,” Bierwisch points out. “So we create a process-structure-property relationship: if we increase the laser power, for example, the microstructure changes, which in turn significantly affects the yield stress of the material. This has a completely different quality than what is possible in experiments. You can detect interrelationships in an almost investigative way.”

Source and image: www.iwm.fraunhofer.de/en