13 Jun AEROTECH: From component supplier to system supplier in the automation process

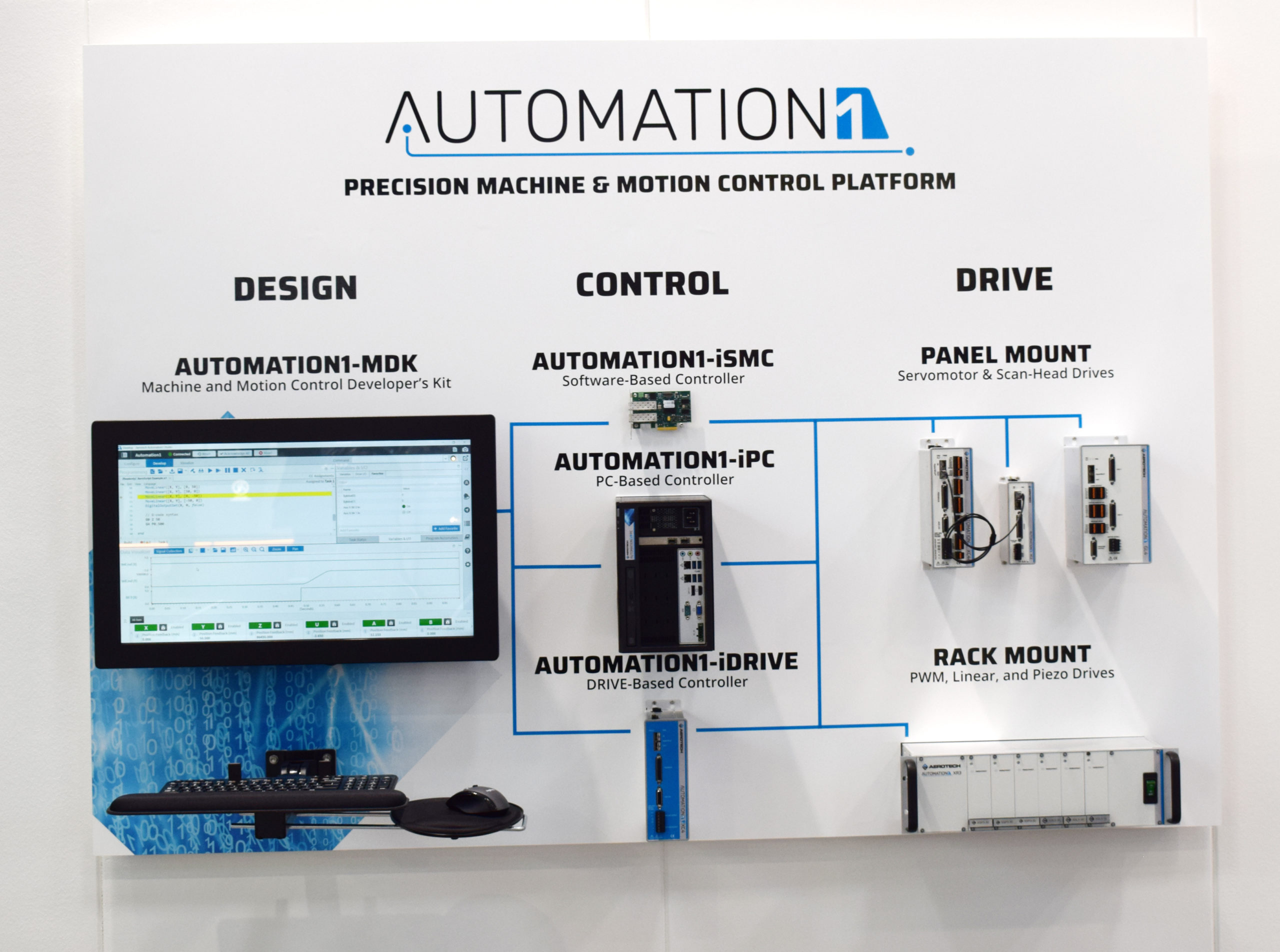

Aerotech, a manufacturer of high-performance motion control and positioning systems, is increasingly becoming a system supplier and supports customers holistically in their high-precision and industry-specific automation processes. Aerotech not only supplies suitable components for particularly difficult operating conditions and mission-critical application areas, but is also increasingly acting as a manufacturer of automation systems for industry-specific applications. Customers have the choice between a pure component solution, a customised motion subsystem up to a fully integrated system.

Since 1970, Aerotech has supplied standard product solutions such as motors, drives, controls and positioning tables. Custom-designed motion subsystems include positioning systems on granite structures with undercarriage and vibration isolation, as well as external measurement systems. Integrated systems are near turnkey machines designed with customers to run an automated process. They include not only Aerotech precision motion control components, but also full automation integration for such things as part handling, process instrumentation, safety features and custom software.

Norbert Ludwig, CEO Aerotech GmbH, Fürth

“In recent years, we have worked closely with customers from a wide range of industries and have also moved further and further into the field of process automation,” emphasises Norbert Ludwig, Managing Director of Aerotech GmbH in Fürth. ,,As a manufacturer of automation systems, we support manufacturing companies in optimally automating their process with the precision motion components we produce.” The manufacturer also wants to support companies that are currently setting up, expanding or modernising their production. Especially in the semiconductor and electronics sector, many companies have neither the personnel nor the vertical range of manufacture to develop mechanics and control systems in parallel,” Norbert Ludwig continues. In addition, the solutions are becoming smarter and more complex, so that a single company can no longer master all the implementation steps. As a result, the know-how of the supplier is becoming increasingly important. And this is where our actual work as a manufacturer of automation systems begins: We offer detailed integration consulting, at the end of which there is either the delivery of individual components, a subsystem that can be seamlessly integrated or a complete automation solution. Application training, courses and services round off our service portfolio.

From electronics manufacturing to medical device manufacturing to additive manufacturing.

Aerotech has a high level of vertical integration, particularly with regard to drive components and control elements. On the mechanical side, Aerotech also supplies partially integrated systems, which the customer only has to complete. If, for example, an adjustment system on granite is required for the machine, Aerotech prepares this for the individual customer. Further additional applications such as laser beam guidance or sensors can then be integrated by the user as required. As a central contact in the field of surface metrology, Aerotech ensures the integration of measuring systems into positioning systems. For manufacturers of measuring systems, Aerotech supplies customised solutions if, for example, a user needs to measure large-area samples that go beyond the scope of standard measuring devices. We have grown with our customers over the years and have gained application knowledge from many industries. Accordingly, we can now recommend the optimal components for the right use in the application,” says Norbert Ludwig.

Integration of Keyence into Aerotech positioning systems for even greater travel: For this purpose, the experts at Aerotech have mounted a Z-axis with up to 300 mm of adjustment travel on a stable granite gantry. The measuring head is supported by an adapter bracket. A cross table is mounted on a granite base for component alignment.

Aerotech – Dedicated to the Science of Motion

Headquartered in Pittsburgh, USA, Aerotech Inc. is a privately held, family-owned, mid-sized company. Founded in 1970 by Stephen J. Botos, Aerotech designs and manufactures the world’s most powerful motion control and positioning systems for customers in industry, science and research. In the spirit of a family business, the owners continue to attach the utmost importance to open and trusting dealings with customers, business partners and employees. In Germany, the medium-sized company is represented by its own subsidiary, Aerotech GmbH, based in Fürth, Franconia. In addition to sales and service activities, the customised assembly of positioning systems for the European market takes place in Fürth. The innovative and high-precision motion solutions meet all critical requirements that are necessary for today’s demanding applications. They are used wherever high throughput is required – including medical technology and life science applications, semiconductor and flat panel display production, photonics, automotive, data storage, laser processing, aerospace, electronics manufacturing, as well as inspection and testing through to assembly. With advanced analysis and diagnostic capabilities, Aerotech provides world-class technical support and service worldwide. If a standard product is not suitable for an individual application, the manufacturer is able to supply special motion components and systems based on its years of expertise and experience. The manufacturing capability for custom applications is further complemented by experience in supplying systems for vacuum and cleanroom operations. Aerotech includes full-service offices in Germany (Fürth), the United Kingdom (Ramsdell), China (Shanghai City) and Taiwan (Taipei City). Aerotech currently employs approximately 500 people worldwide.

Source and photos: https://de.aerotech.com/