14 Jun Metamaterial from the 3D printer makes sound waves travel backwards

Researchers dream of designing metamaterials on the computer and then producing them directly on the 3-D printer. Such materials could be used, for example, to direct sound in an unnatural way.

Metamaterials have optical, acoustic, electrical or magnetic properties that do not occur in nature. Researchers at the Karlsruhe Institute of Technology (KIT) want to develop a metamaterial that allows acoustic waves to be manipulated in a way that has never been achieved before. A 3-D laser printer is to be used for the production.

Acoustic waves in gases, liquids and solids usually have an almost constant speed of sound. Quasiparticles called rotons are an exception: With them, the speed of sound changes significantly with the wavelength, and backward travelling waves are also possible.

For certain frequencies, three different partial waves occur. “The slowest of them is a backward wave: the energy flow and the wave fronts run in exactly opposite directions,” explains Professor Martin Wegener from the Institute of Applied Physics (APH) and the Institute of Nanotechnology (INT) at KIT.

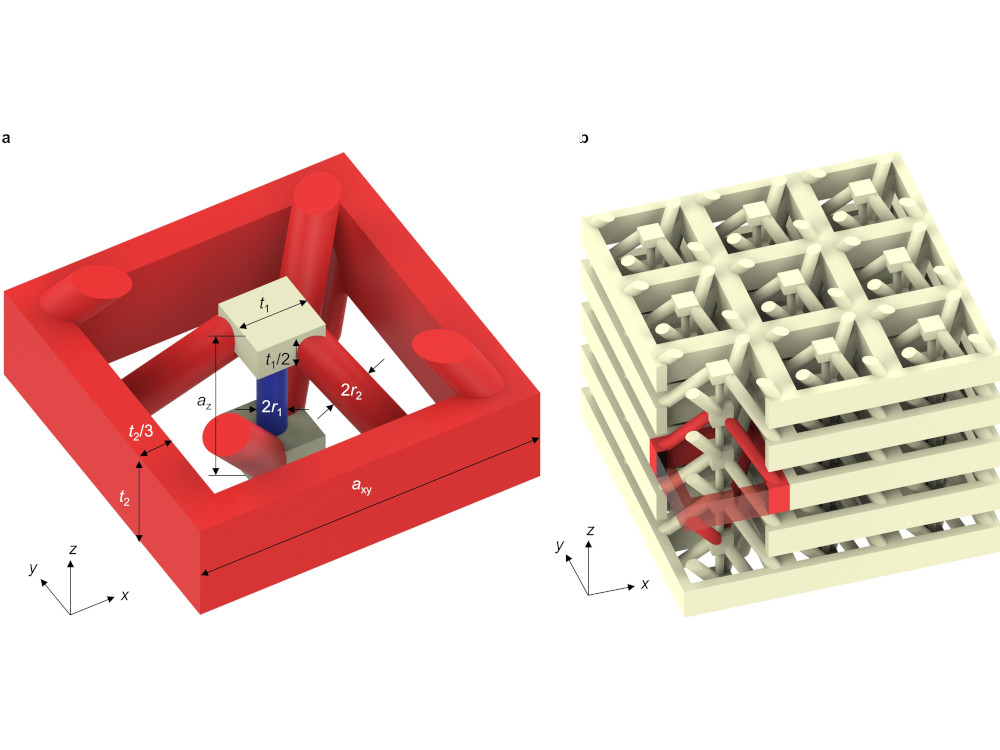

The scientists propose such an artificial material that exhibits rotons completely without quantum effects under normal ambient conditions and at almost freely selectable frequencies (image). This could make it possible in future to better manipulate sound waves in air or in materials, for example to reflect them back, redirect them or generate echoes. “In general, we have the dream of designing materials on the computer and then transferring them directly – without years of trial and error – into reality. 3D printing is then, as it were, just an automated converter from the digital to the physical world,” explains Professor Martin Wegener.

Original publication

Roton-like acoustical dispersion relations in 3D metamaterials, Yi Chen, Muamer Kadic and Martin Wegener, Nature Communications volume 12, Article number: 3278 (2021), DOI: 10.1038/s41467-021-23574-2]

Source and photo: www.kit.edu (Image: Yi Chen, KIT)