10 Dec Junior research group develops copper alloys for 3D printing

Over the next five years, Dr Silja-Katharina Rittinghaus aims to develop new copper-based materials for 3D printing with a focus on sustainability. The scientist from the University of Wuppertal is receiving around two million euros from the Federal Ministry of Education and Research to set up a new junior research group.

A disadvantage of pure copper

Although pure copper, which can also be processed as a metallic powder in a 3D printer, is the most conductive material to be used for heat dissipation in electronic components, it is also a relatively soft material. In order to fulfil the highest technical requirements, the material used must be stronger. This is achieved using copper alloys, i.e. compounds with other metals. The problem is that conventional materials are no longer as conductive as pure copper, meaning that the parts made from them do not utilise the full potential of their cooling capacity. The search is therefore on for new alloys with ideal properties in terms of both thermal conductivity and strength.

A nanocomposite made from three elements

“In the Nanostew project, we are looking for a new material composition that is as strong as possible and as conductive as possible in order to use it for the production of components in additive manufacturing, i.e. in 3D printing,” says Rittinghaus. Nanostew stands for ‘nanocomposed melting materials and their texture design for efficient heat transport in structural components’. The project is focussing on tiny parts: Nanoparticles of silver and yttrium oxide. In combination with other elements, silver increases the strength of the metallic material mixture without negatively affecting its conductivity. Yttrium oxide ensures that the material becomes stronger even at high temperatures – also without impairing its conductivity. An innovation is now to combine both materials with copper at the same time. “We have set ourselves the task,” summarizes Rittinghaus, “of combining copper, silver and yttrium oxide in the best possible way and developing new composite powders for 3D printing and testing them for two applications at the same time.” Together with her project sponsors, Rittinghaus wants to use the developed material to manufacture parts for a drive component for the aerospace industry and to coat a ceramic cooler with copper for thermal management in electronic devices and components. In future, the cooler could be used in the field of electromobility, for example in battery management systems, where it helps to control the temperature.

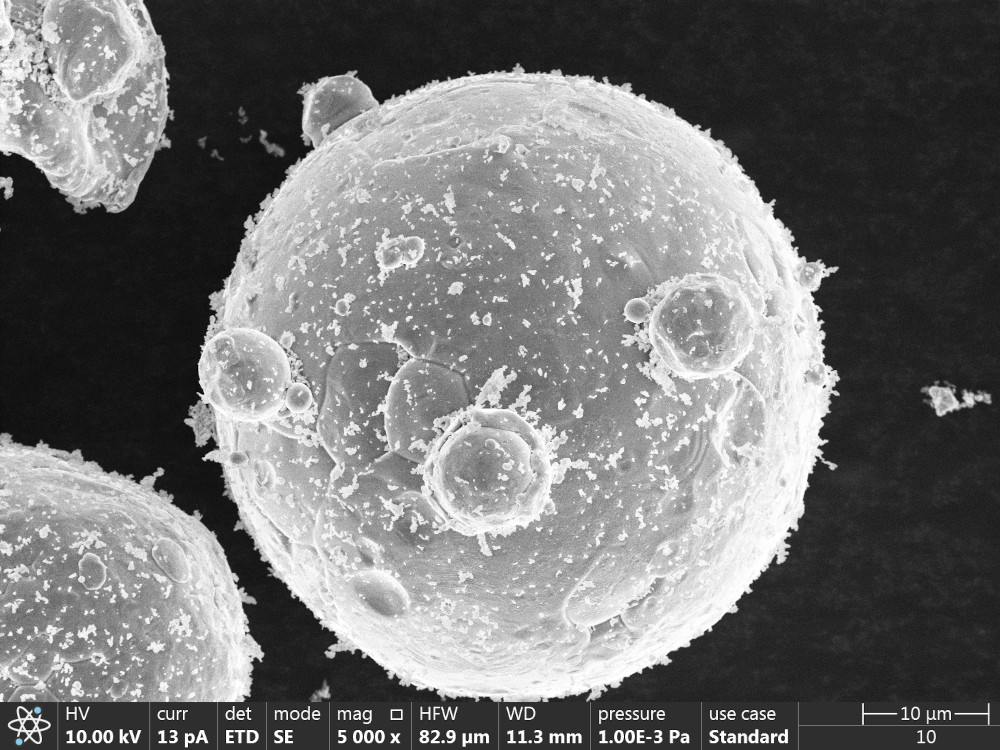

Image taken with a scanning electron microscope: The tiny nanoparticles adhere to the larger copper microparticle – the composite is formed. Image: Tobias Bochman / ICAN

Focus on sustainability

The research group is also focussing on the recycling process as an additional component. The aim is to make the entire production of the new material mixture as resource-efficient as possible – on various levels. “On the one hand, we are looking at how useful copper is for our powder, which we can obtain as a secondary raw material from other products,” explains Rittinghaus. “In our project, for example, this is copper from discarded solar panels.” The researchers are also considering how the copper from the production trials can be recycled if it does not yet have the desired properties.

Transferable Knowledge

Over the various project stages, the project brings together researchers with expertise from very different fields: materials science, materials engineering, chemistry and nanotechnology, as well as physics, process engineering and computer science. The project is also supported by mentors from industry. Rittinghaus: “In this way, we want to ensure that both scientific and technical aspects are taken into account and that economic realisation is possible.” The fact that the project is developing components for two different applications – aerospace technology and electronics – that differ in terms of their geometric and functional requirements is intended to highlight the potential, flexibility and transferability of the solutions developed to other material systems. “In Nanostew, we use materials research to provide impetus for new applications and to make important technologies more future-proof and sustainable,” says Rittinghaus.

From 1 January 2025, Silja-Katharina Rittinghaus will head the Nanostew junior research group at Prof. Dr Bilal Gökce’s Chair of Materials for Additive Manufacturing.

Source and image: www.uni-wuppertal.de