06 Dec From lab to product: quantumdot IR detector

Detectors for infrared radiation usually consist of a crystalline semiconductor material and electronics for reading out the data. The semiconductor materials are often complex to manufacture, which has to take place at very high temperatures and consumes a lot of energy. Researchers at the Swiss Federal Laboratories for Materials Science and Technology (Empa) were convinced that there is another way and developed new detectors for infrared radiation that are more sustainable, flexible and cost-effective than previous technologies. A team led by Ivan Shorubalko from the Transport at Nanoscale Interfaces laboratory is working on miniaturized infrared detectors made from colloidal quantum dots.

Shorubalko explains: “The properties of a material depend not only on its composition, but also on its dimensions.” This means that if the smallest nanoparticles are produced from a material, they often have different properties than larger pieces of the same material. The reason for this are quantum effects, hence the name quantum dots. The simplicity of quantum dots lies in their processing: colloidal quantum dots, that means quantum dots in a solution, can be applied to different materials by means of spin coating or printing – and this is cheaper, more energy-efficient and more flexible than with conventional semiconductors.

From the material to the process to the application

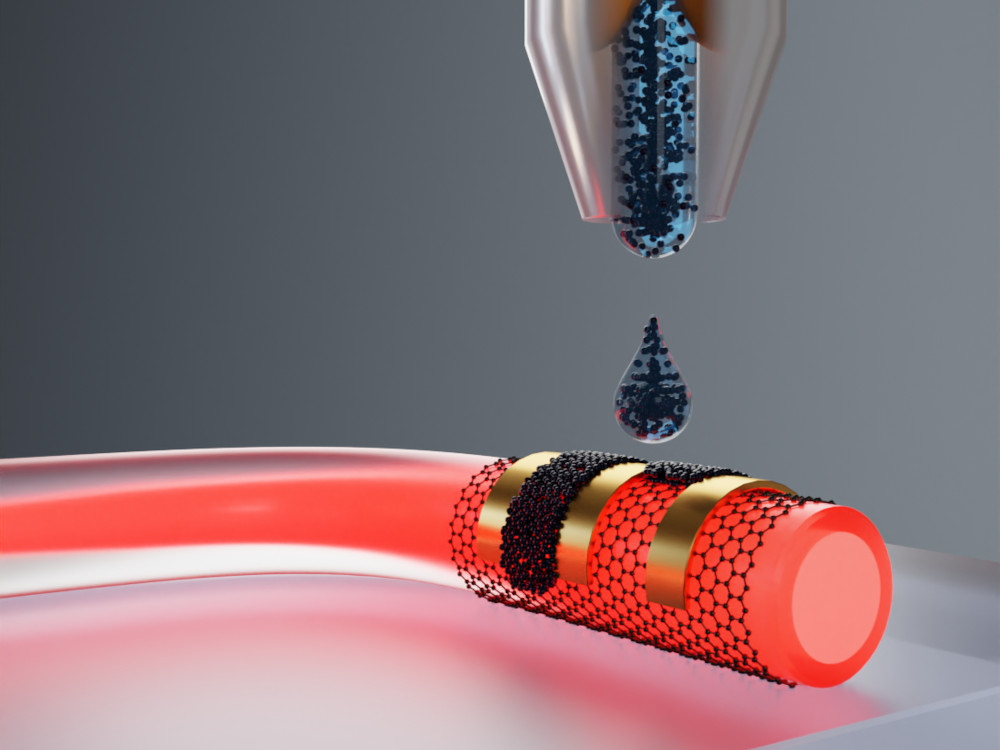

Shorubalko and his team produce functioning electronic components from the quantum dots. Together with other Empa experts, they are also researching processing methods and other applications for quantum dots. For example, the Empa researchers have succeeded in printing an infrared detector made of quantum dots onto an optical polymer fiber – something that is not possible with conventional infrared detectors.

One possible application of this technology would be smart textiles. Special textiles in particular could benefit from the flexible infrared detectors, for example functional clothing for firefighters or medical textiles for patient monitoring. However, Shorubalko also sees great potential in fashion: “If detectors and other electronic components are small, cheap and easy to manufacture, we can also functionalize our everyday clothing with them.”

High speed for lidar

Next, Shorubalko wants to improve the speed of the detector. Fast infrared detectors are needed for lidar, for example. “Silicon-based infrared detectors in lidar sensors measure infrared light with a wavelength of around 905 nanometers,” explains Shorubalko. The problem: although this wavelength is invisible to the human eye, it is still harmful at high power. This is why the laser in the lidar can only emit weak radiation, which in turn limits the range of the entire system. Detectors for non-hazardous wavelengths do exist, but are too expensive to be used on a large scale. A fast detector based on quantum dots could offer an alternative and enable powerful, harmless and cost-effective lidar systems.

From lab straight to product

Unlike many other new technologies and materials, infrared detectors made from quantum dots are already available on the market, emphasizes Shorubalko. “I’ve never seen a technology that has made the leap from the lab to the field so quickly.” Nevertheless, the researchers believe that the work is far from over. The task now is to make this promising technology even faster, more cost-effective, more flexible and more sustainable.

Source and image: www.empa.ch