07 Feb Lasered microlenses against nearsightedness

Microlenses on spectacle lenses can help to reduce the growth-related deterioration of nearsightedness and thus prevent possible secondary diseases. This is particularly important for nearsightedness in children. According to statistics, around 33 per cent of children and adolescents over the age of five worldwide are currently nearsighted. Late consequences of nearsightedness can include retinal detachment, cataracts or macular degeneration. In order not only to correct vision, but also to counteract the progression of nearsightedness and possible secondary diseases, special spectacle lenses for children already contain microlenses: by superimposing a focal point in the periphery, they slow down the longitudinal growth of the eyeball, which triggers the progression of myopia.

Highly flexible and cost-effective production

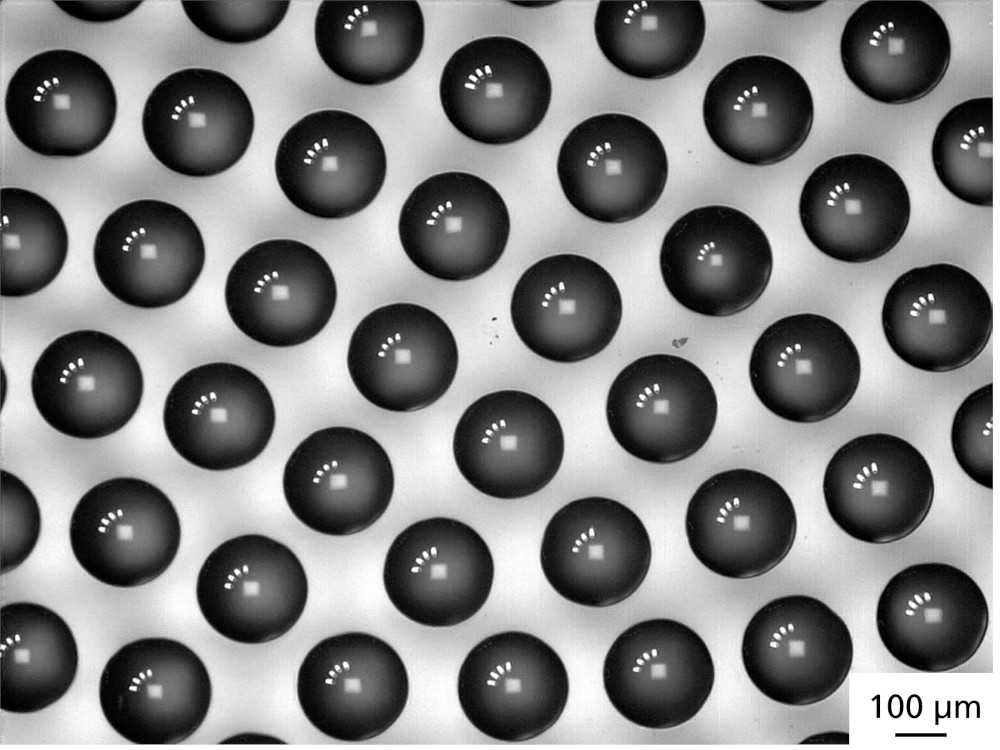

Researchers at the Fraunhofer Institute for Microstructure of Materials and Systems IMWS have now reported on a new method that can be used to produce microlenses in a more cost-effective and customized way. The laser, which serves as a localised heat source, excites water molecules contained in the polymer. The molecules move, creating an internal pressure that can only be released upwards. This creates a bulge on the surface that remains even after irradiation: a microlens.

“As the laser beam can be positioned very precisely on surfaces, we can produce significantly smaller microlenses than with the previous process,” explains Prof Thomas Höche, initiator of the technology and head of the Optical Materials and Technologies business unit at the Fraunhofer IMWS. “This means that the microlenses can be arranged very flexibly on spectacle lenses – and can therefore also be customized for small spectacle wearers.” Höche adds: “With laser swelling, we are also very flexible when it comes to the size of the microlenses and their shape. Everything can be realized, from spherical to aspherical to cylindrical lenses.”

Without tools and plastic waste

In addition to individualization, laser swelling has other decisive advantages compared to the previous production method. In the injection molding process used to date, the polymer is pressed into a glass or metal die and then removed from the mold. This process is not only time-consuming, but the tools also have to be cleaned and replaced over time. Laser swelling, on the other hand, does not require any tools; the process is contactless. As no material is removed, no microplastics are produced.

Not only suitable for glasses

According to Höche, laser swelling can also be used in various other areas, for example to create microlenses on intraocular lenses, for microfluidic components, to improve the adhesive properties of polymer surfaces or for compact microscopes. Laser swelling can also be used to discreetly mark medical products such as syringes: Medication or vaccines, for example, can be provided with a code that contains a tracking number and becomes visible with the appropriate lighting. This could provide information as to whether it is an original product.

According to the researchers, their current focus is still on the spectacle lens industry: “Our vision is an individualized visual aid that can be tailored to the needs of specific professional groups,” explains Höche.

Source and image: www.fraunhofer.de