09 Sep New R&D center for transparent ceramics

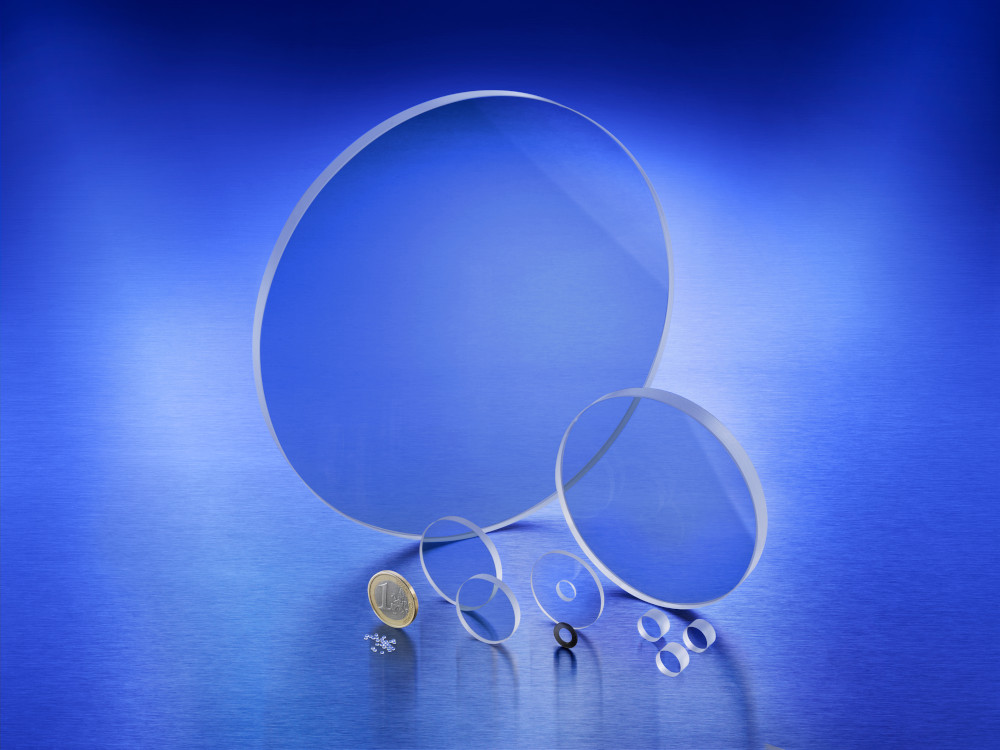

As transparent as glass, but as heat-resistant and scratch-proof as ceramic – transparent ceramic is a special material whose production requires not only special expertise, but also specialized equipment and systems. In the future, transparent ceramics will be able to utilize their advantages of robustness, hardness, transmission and cost-effectiveness over glass and sapphire to an even greater extent. The reason: the Fraunhofer Institute for Ceramic Technologies and Systems IKTS opened a new research and development center for transparent ceramics at the end of August in order to develop innovative, economical applications with industrial partners.

For research and co-operation

The new infrastructure includes equipment and systems for conditioning high-purity powders, moulding, heat treatment, laser and ultra-precision processing. ‘The most important tasks we have set ourselves are firstly to produce transparent ceramics in excellent quality on a pilot and series scale,’ emphasises Dr Martin Drüe, Group Manager for Transparent Ceramics at Fraunhofer IKTS. ‘Purity and high transparency play a decisive role here. On the other hand, we are looking forward to exciting, forward-looking development work together with industrial partners. This will not only involve analysing and developing materials, designing or shaping the ceramics, but also application-specific issues relating to system integration. This is because it often concerns applications that require transparent ceramics in combination with other materials such as glass, titanium or precious metals.’

The research and development center for transparent ceramics is said to be unique in Europe. ‘We now have an infrastructure for the entire process chain for the production of transparent ceramic components, not only in the laboratory, but also on a pilot and series scale,’ says Dr Sabine Begand, Head of the Oxide Ceramics department. ‘This allows us to greatly expand our expertise and the range of applications for transparent ceramics.’ This leap in expertise is now possible because IKTS has taken over the transparent ceramics division and the Perlucor brand from Ceramtec-Etec. According to the Fraunhofer Institute, around 20 production systems and 100 small devices with a production area of 700 m² have since been integrated into the institute’s infrastructure at the Hermsdorf site. The Free State of Thuringia subsidised this measure with 2.5 million euros.

The hot isostatic press (HIP) is a centerpiece of the numerous systems in the R&D center. Here, the ceramic components are thermally compressed at up to 2000 °C and 2000 bar. Image: Fraunhofer IKTS

Industrial partners can use the technical infrastructure of the R&D center as a service, carry out tests and benefit from the results of mechanical tests, laminating and printing tests, for example, according to the Fraunhofer Institute. Prototypes and pilot series with quantities of around 10,000 units as well as an almost fourfold increase in component size will now be possible. The joining of transparent ceramics is also the focus of development in order to further increase the variety of geometries. In addition, the IKTS researchers say they have set themselves the goal of steadily increasing the reproducibility of component production.

Hard, temperature-resistant and chemically stable

According to the researchers, transparent ceramics have excellent mechanical and optical properties: The material is four times harder than glass and has significantly better transmission of light rays, even in the infrared and UV range. The material is also said to be characterised by high scratch resistance, temperature resistance and thermal conductivity. According to the researchers, the material’s high hardness makes it ideal for ballistic protection applications – for example, in combination with substrates such as glass or plastic, the component can be made significantly thinner with the same protective effect, which reduces material and therefore weight. Transparent ceramics also show their strengths in areas such as autonomous driving, driver assistance, transport, aviation and laser head protection systems. In addition to the excellent transmission and mechanical properties, the chemical stability and biological compatibility of transparent ceramics are ideal for applications in medical technology, such as microimplants. Interactive display screens such as head-up displays also need to be robust yet lightweight. This is particularly important for manufacturers of mobile devices and other high-end applications, for which the researchers believe transparent ceramics are virtually predestined.

Industries that can benefit greatly from transparent ceramics include optics, optoelectronics, civil defence, security technology, medical technology, laser and sensor technology, scanner and display technology, the automotive and aerospace industries and mechanical engineering.

Weblink to the Transparent Ceramics Group at Fraunhofer IKTS

Source and image: www.ikts.fraunhofer.de