13 Aug Infineon orders laser trimming system from 3D-Micromac

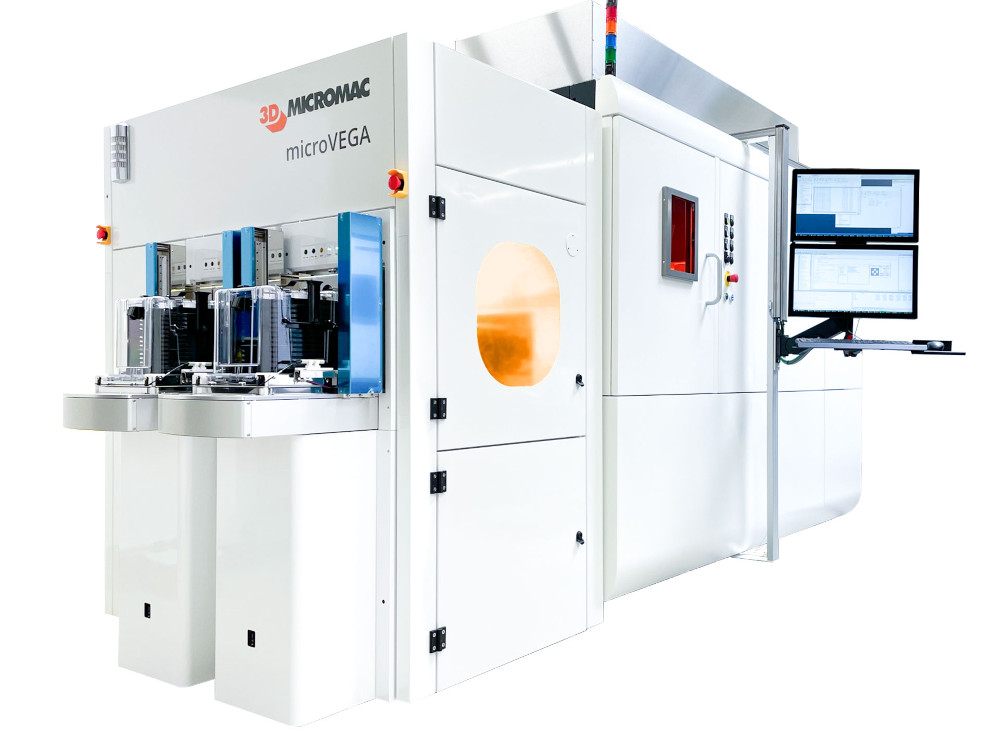

3D-Micromac from Chemnitz will provide Infineon Technologies Dresden with production equipment for laser trimming. According to the companies, the order was preceded by a joint development project in which the highly specialized laser trimming process was converted into a laser system suitable for mass production. The Microvega system from the laser micromachining specialist, which is already used for processing wafers up to 12 inches in size in the semiconductor industry, served as the basis. Infineon has now ordered its first Microvega FC laser system from 3D-Micromac for its new plant, the Smart Power Fab, in Dresden.

“The experience and innovative strength of 3D-Micromac and the close dialogue between the specialists of both partners have made this development project a success,” says Raik Brettschneider, Managing Director of Infineon Dresden. Equipping further Infineon production sites with highly specialized laser trimming solutions from 3D-Micromac is a jointly declared goal, the partners emphasize.

By choosing the manufacturer from Chemnitz, Infineon has opted for European production technology: “We are delighted that Infineon has chosen 3D-Micromac as its supplier for laser trimming technology,” summarizes Uwe Wagner, CEO of 3D-Micromac. “We are proud to support the European Commission’s goal to increase the European share of semiconductor production and to contribute to better securing value chains in key European industries.”

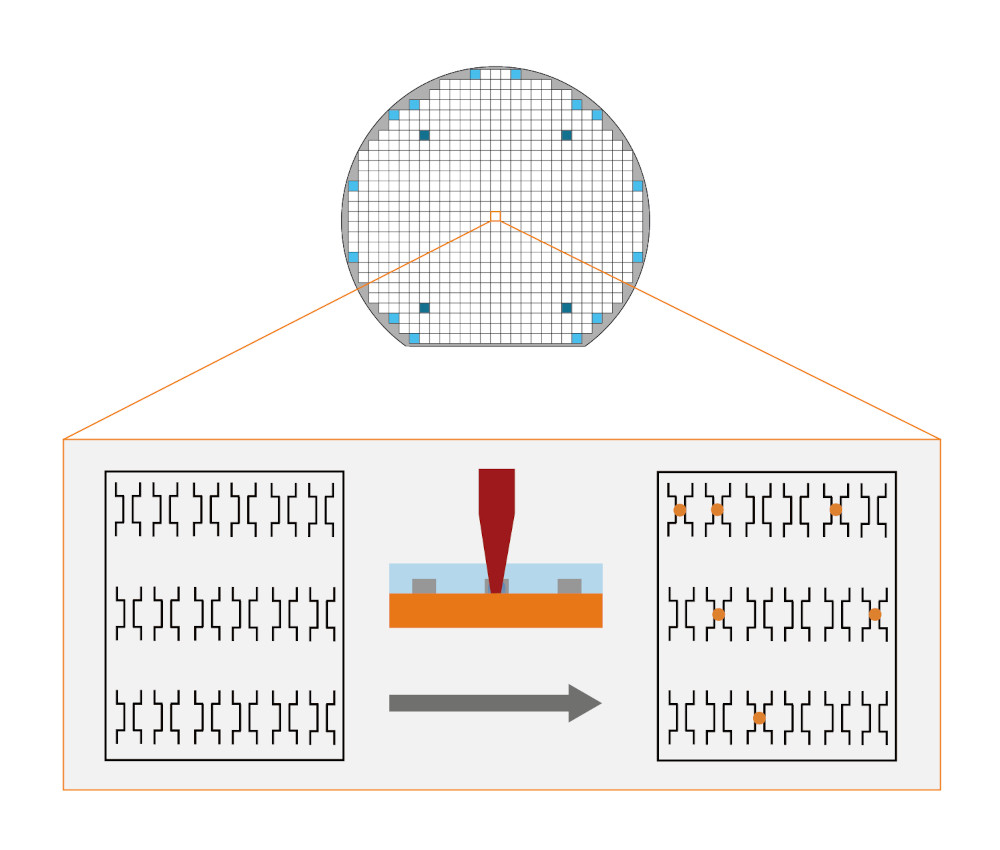

In link trimming, the resistance values of individual IC chips are adjusted to a target value by processing defined microstructures. Image: 3D-Micromac

Analogue/mixed-signal technology and power semiconductors from Dresden

According to Infineon, the Smart Power Fab currently under construction will produce analogue/mixed-signal technologies and power semiconductors from autumn 2026. These will primarily be used in power supply systems. The interaction of power semiconductors and analogue/mixed-signal components will enable particularly energy-efficient and intelligent system solutions in energy-efficient chargers, small motor controllers for cars, data centers and applications in the Internet of Things.

Laser trimming in chip production

In the Microvega FC, the laser beam, which is shaped in the single-digit micrometer range, is moved continuously over semiconductor chips. During this movement, defined connections on the semiconductor wafers are selectively cut according to specifications. This trimming process adjusts the resistance value in individual IC chips to a target value. Due to the small size of the structures of around 1 to 2 µm and the resulting extremely high demands on the three-dimensional positioning accuracy of the laser spot, the machine hardware must fulfil the highest requirements. According to the manufacturer, the measurement technology implemented for 100 % process control is particularly challenging. The Microvega FC system has fully automatic handling for 8 and 12-inch wafers. At process speeds of up to 400 mm/s, the system is said to achieve a positioning accuracy of ± 200 nm.

Source and image: 3d-micromac.de