04 Jul An optical lens that senses gas

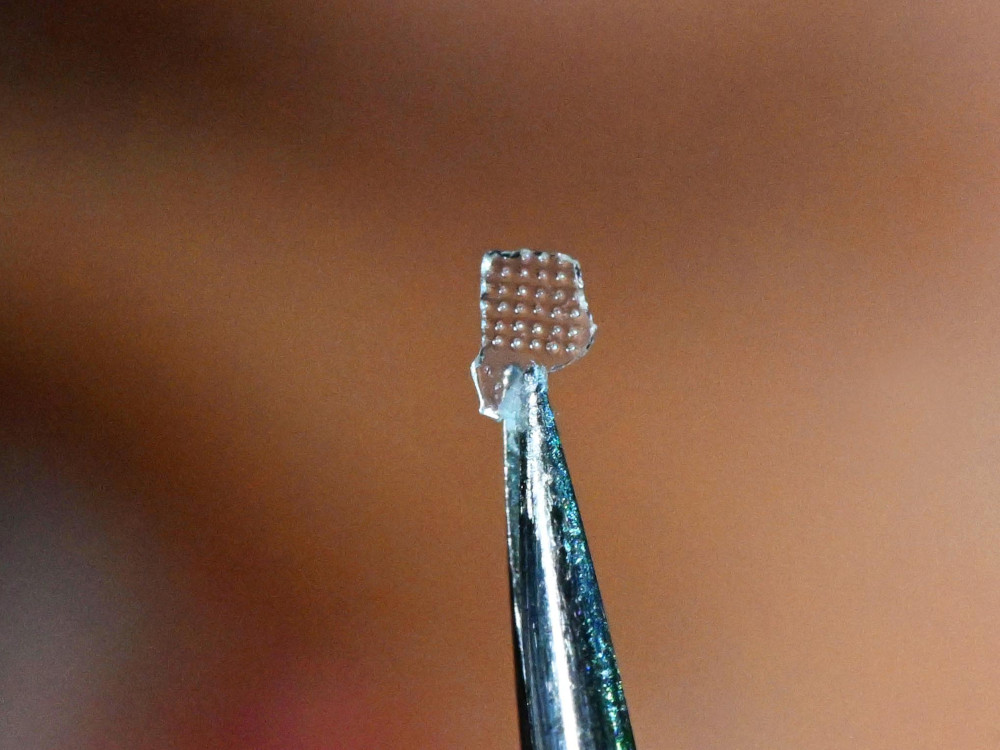

A team of researchers at the University of Jena has developed an optical lens just a few millimetres in size whose refractive behavior changes when gas is present. The molecular structure of the lens consists of a three-dimensional lattice in whose cavities gas molecules can be absorbed – which in turn affects the optical properties of the material.

Gas-dependent light refraction

“With the support of the Carl Zeiss Foundation, we are developing so-called multiresponsive materials,” explains Lothar Wondraczek, Professor of Glass Chemistry at the University of Jena. “Using the example of the hybrid glass lens, this means that it refracts the light more or less strongly depending on whether gas is absorbed in the lens material or not.” The challenge here was to transfer methods of classic glass moulding to these special materials. “The metal-organic framework compounds that we used here are being researched and developed as materials for storing or separating gases,” explains Wondraczek. Oksana Smirvona, PhD student in the research project, adds: “However, most of these substances decompose when heated and are therefore very difficult to mould.”

Together with Dr Alexander Knebel, junior research group leader at the Chair of Glass Chemistry, the Jena researchers first had to develop a suitable synthesis process for high-purity materials. They then had to identify the optimum conditions under which the material could be moulded into the desired shape. “We melt the material and then transfer it to a 3D-printed negative mould in which it is pressed,” explains Smirvona. “Within this process, the desired shape can be chosen almost at will. We deliberately chose the lens as the mould,” she continues. Because: “With a lens, even the smallest impurities are noticeable as they directly influence the optical properties.”

Material for intelligent sensor technology

With this new process, a wide variety of shapes and geometries are now conceivable that go beyond the specific application as microlenses, explains Wondraczek. “Because these multi-responsive materials react to several influences simultaneously, they can be used for logical circuits, for example,” says the materials scientist, describing possible applications for such components. “In concrete terms, this means that two conditions are linked for the observable reaction,” he explains. “For example, if a beam of light falls on the lens and a gas is absorbed in the lens material at the same time, the light is refracted in a certain way and can thus provide combined feedback.” It would therefore also be possible to develop membranes for gas separation whose optical properties change when gas molecules are inside them. Such optical components could be used in sensor technology, for example, and could make measurement processes more efficient, space-saving and intelligent.

Original publication:

[Oksana Smirnova, Roman Sajzew, Sarah Jasmin Finkelmeyer, Teymur Asadov, Sayan Chattopadhyay, Torsten Wieduwilt, Aaron Reupert, Martin Presselt, Alexander Knebel & Lothar Wondraczek: „Micro-optical elements from optical-quality ZIF-62 hybrid glasses by hot imprinting”, Nature Communications, 2024 (15) 5079. DOI: https://doi.org/10.1038/s41467-024-49428-1]

Source: www.uni-jena.de

Image: Jens Meyer / Friedrich Schiller University Jena