05 Dec AI for perovskite solar cells: the key to better production

Perovskite tandem solar cells combine a perovskite solar cell with a conventional solar cell, for example based on silicon. They are considered next-generation technology as they are much more efficient than conventional silicon solar cells with a current efficiency of more than 33% – with low-cost raw materials and simple production methods. In order to bring this technology to the market, stability and production processes must be further improved.

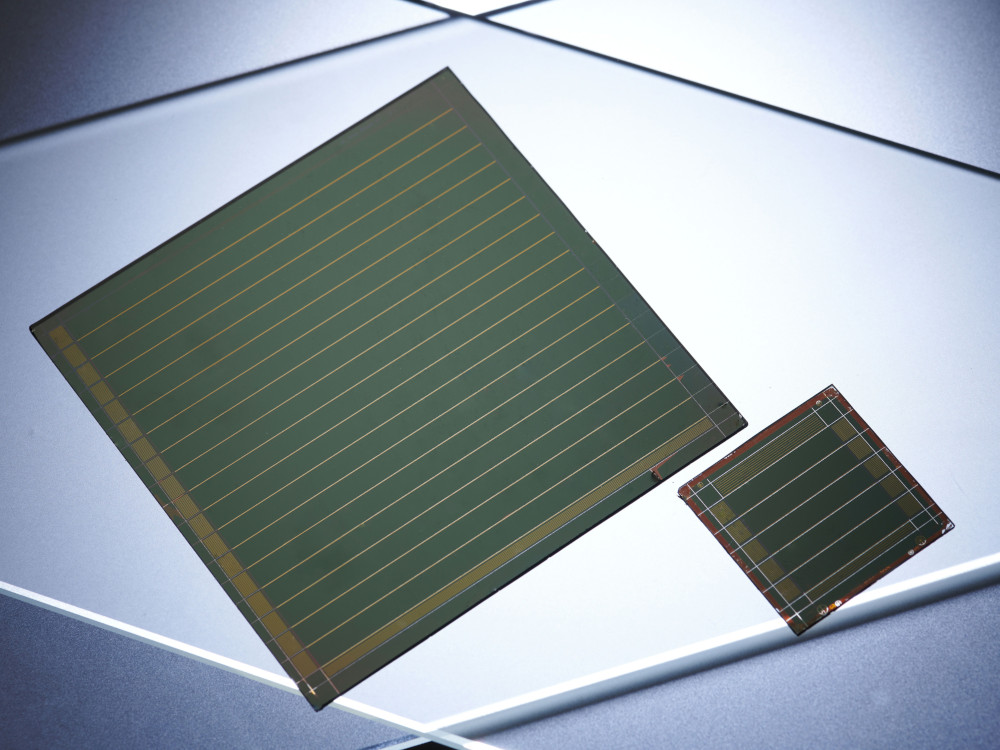

Layer quality is crucial

The prerequisite for achieving this level of efficiency is a very high-quality and extremely thin perovskite layer. “One of the biggest challenges is to produce these high-quality so-called multicrystalline thin films using cost-effective and scalable processes without defects and holes,” explains tenure-track professor Ulrich W. Paetzold from the Institute of Microstructure Technology and the Light Technology Institute of the Karlsruhe Institute of Technology (KIT). Even under apparently perfect conditions in the laboratory, unknown influences lead to fluctuations in the quality of the semiconductor layers: “This ultimately prevents the rapid start of industrial production of these highly efficient solar cells, which we so urgently need for the energy transition,” says Paetzold.

Photoluminescence reveals coating quality

To find out which factors influence the coating, an interdisciplinary team of perovskite solar cell experts from KIT has joined forces with specialists in machine learning and explainable artificial intelligence (XAI) from Helmholtz Imaging and Helmholtz AI at the German Cancer Research Center (DKFZ) in Heidelberg. The researchers have developed AI methods to train and analyze neural networks using a large data set. The data set includes video recordings of the photoluminescence of the perovskite thin films during the manufacturing process. Photoluminescence refers to the radiant emission of the semiconductor layers after excitation by an external light source. “Since even experts could not recognize anything remarkable on the thin films, the idea arose to train an AI for machine learning (deep learning) to find hidden indications of a good or bad coating in the millions of data from the videos,” explain Lukas Klein and Sebastian Ziegler from Helmholtz Imaging at the DKFZ. In order to filter and analyze the very broadly scattered indications of the deep learning AI, the researchers subsequently used methods of Explainable Artificial Intelligence.

AI predicts the efficiency

The result: the researchers were able to recognize in the experiment that the photoluminescence varies during production and that this influences the coating quality. “The decisive factor in our work was that we used XAI methods specifically to see which factors would have to change for a high-quality solar cell,” say Klein and Ziegler. This is not usually the case. Usually, XAI is only used as a kind of guard rail to avoid errors when building AI models: “This is a paradigm shift, and the fact that we can systematically gain highly relevant knowledge in materials science in this way is new.” The answer to the variation in photoluminescence enabled the researchers to go further. According to the researchers, after training the neural networks accordingly, the AI was able to predict whether the solar cell would achieve low or high efficiency depending on the variation in light emission during production. “These are extremely exciting results,” says Paetzold. “Thanks to the combined use of AI, we have an idea of which adjustments we need to make first and foremost in order to improve production. We can carry out our experiments in a more targeted manner and no longer have to search for a needle in a haystack in the dark. This is a blueprint for follow-up research, including for many other aspects of energy research and materials science.”

Original publication:

[Lukas Klein, Sebastian Ziegler, Felix Laufer, Charlotte Debus, Markus Götz, Klaus Maier-Hein, Ulrich W. Paetzold, Fabian Isensee, Paul F. Jäger: Discovering Process Dynamics for Scalable Perovskite Solar Cell Manufacturing with Explainable AI. Advanced Materials, 2023. DOI: 10.1002/adma.202307160]

Source: www.kit.edu

Image: Amadeus Bramsiepe, KIT