01 Dec Titan, nickel and stainless steel: reference data for improved 3D printing

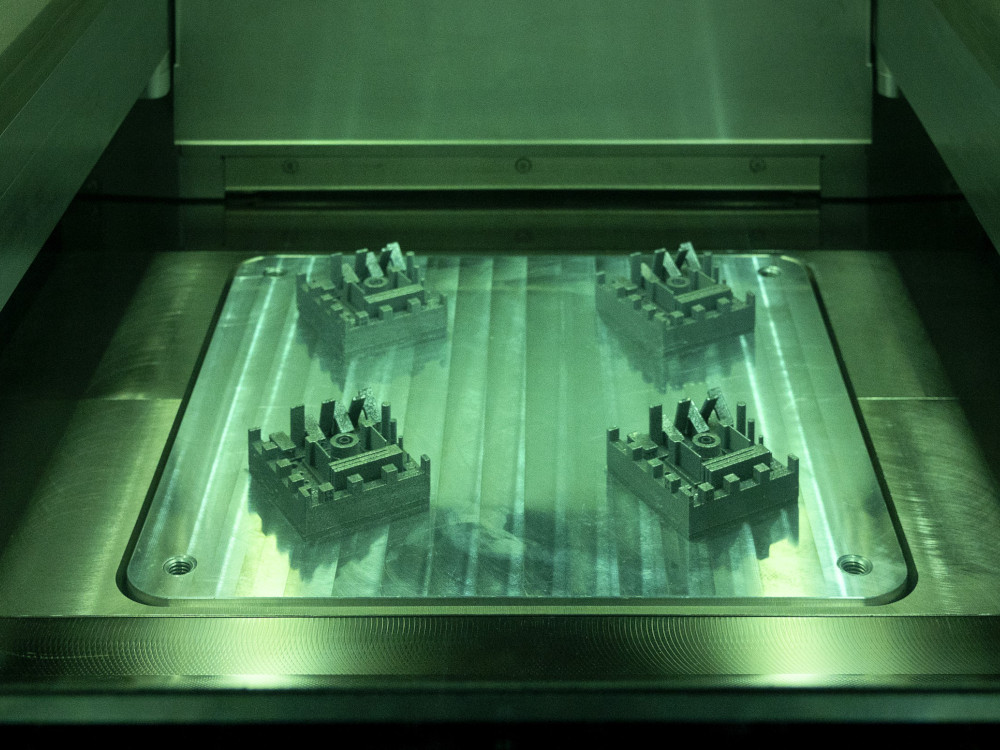

The Bundesanstalt für Materialforschung und -prüfung (BAM) (Federal Institute for Materials Research and Testing) has published for the first time reference data on additively manufactured materials made of titanium, nickel and a stainless steel. The data’s purpose is to ensure the quality and safety of components and drive forward material development in 3D printing.

Elastic properties vary depending on direction

The team led by scientists Dr Birgit Rehmer and Professor Birgit Skrotzki from the Materials Engineering Department and the Competence Centre Additive Manufacturing at BAM has characterized three metal alloys using the Dynamic Resonance Method (DRM). This involved exciting the material with a periodic mechanical impulse and measuring the resulting resonance frequencies. They discovered, for example, that 3D-printed components exhibit significant differences in their elastic properties depending on the installation direction and the direction in which the samples are removed.

The directional dependency, which occurs at all the temperatures investigated, has an impact on use in specific applications, such as turbine blades. This must be taken into account when designing components in which the direction of loading plays a role, the researchers explain. The parameters of the additive manufacturing process also influence the properties. For example, a thinner powder coating thickness results in higher elastic characteristic values for stainless steel.

“To minimize potential risks and ensure the quality of 3D-printed components, reliable reference data is essential,” explains Skrotzki. “Our reference data on the elastic properties of additively manufactured metals is an important contribution that not only ensures the quality and safety of these components, but also enables innovations in material development.”

In areas such as aerospace and medical technology, the safety of materials is of great importance, as faulty components can have serious consequences. The unique microstructures created by additive manufacturing influence the mechanical, thermal and chemical properties of a component, such as its strength or corrosion resistance.

Available immediately

The extensive data sets contain information on the manufacturing processes and parameters, heat treatments, grain size, sample dimensions and weight together with their measurement uncertainties. They can be used by designers, testing laboratories and researchers to evaluate the performance of additively manufactured materials, carry out quality tests and improve simulations. The reference data is now available via the Zenodo open data platform.

Lecture series: Quality assurance in additive metal manufacturing

In addition to the development of reference data, BAM says it regularly offers training courses and workshops on the topic of additive manufacturing. Interested parties can register free of charge at www.bam-akademie.de.

Download the reference data for stainless steel

Download the reference data for nickel materials

Download the reference data for titanium materials

Source and image: www.bam.de