16 Jan Scalable process gas cleaning for 3D printing

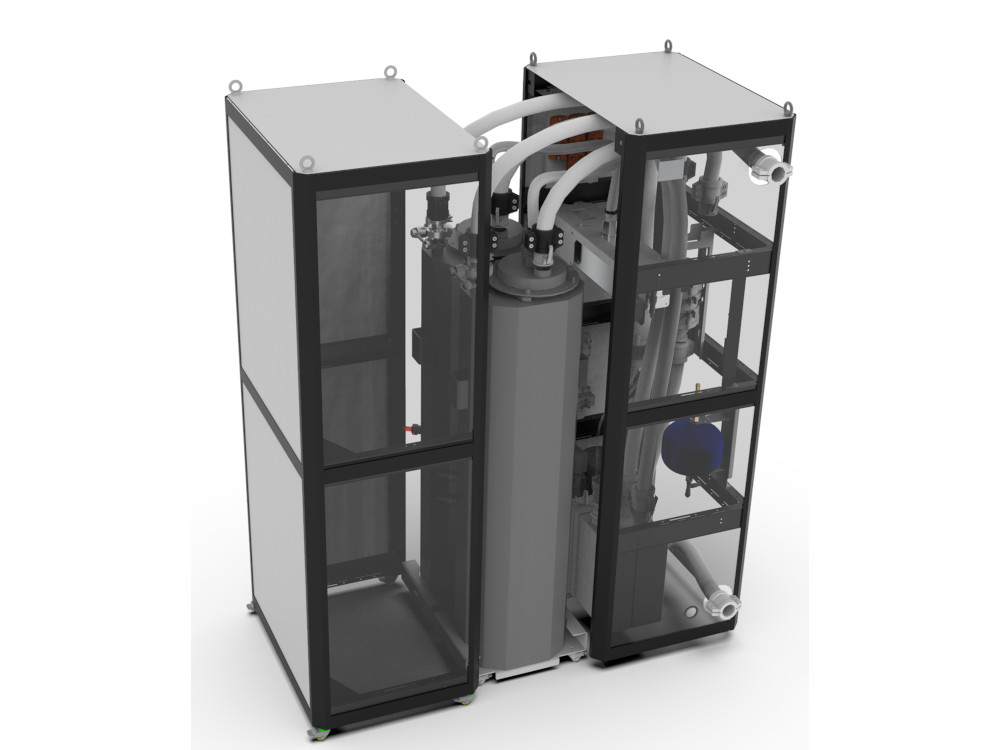

The AMF 200 from ULT is a system for process gas cleaning in metallic 3D printing (laser powder bed fusion, LPBF). According to the manufacturer, it is a modular, open and standard-components based, cost-optimized extraction and filter system for additive manufacturing systems of different sizes.

Based on the supplier’s information, advantages of the system are a simple operation and its scalability. In addition to a standard volume flow of up to 200 m³/h at a negative pressure of 10,500 Pa (N2, 50 °C) / 15,000 Pa (Ar, 50 °C), the system can be variably adapted to higher or lower gas flows – without being dependent on the supplier or print volume sizes of the 3D printers.

According to the manufacturer, the filter and powder handling is contamination-free. The footprint is 800 x 1200 mm2. The system can be operated as a slave with I/O system, or as a stand-alone machine with its own configured control system.

Additional features include automated filter cleaning, the use of a side-channel blower with a mounted frequency converter, or various sensors e.g., for oxygen, volume flow, temperature as well as differential pressure filter stages or fill level filter cells.

Further information from the manufacturer

Source and image: www.ult-airtec.com