14 Jun The decisive component

What began over 100 years ago with the theory of stimulated emission is now an indispensable technology for industry: laser technology. In order for the beams to be optimally focused or guided, it requires metal optics – an optical component with particularly high precision.

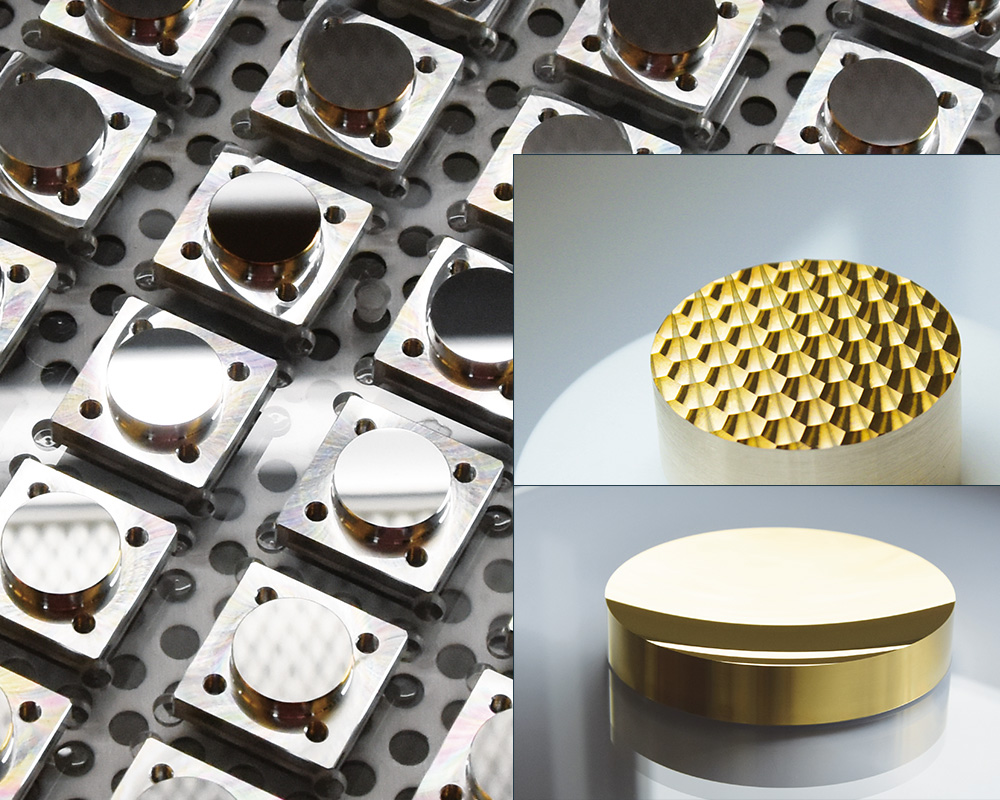

IMOS Gubela GmbH manufactures such complex surfaces, among other things, and supplies the smallest optical structures for ultra-precise and high-performance laser results.

The optics specialist

It is not for nothing that the name IMOS stands for “Institute for Microoptics and Structures”. Since the company was founded in 1994, it has developed and produced exclusively in the field of optics. Thus, with each new product, the team’s experience grew and at the same time inspired new projects. IMOS optics are used in laser technology, sensor technology, measurement technology, astrophysics, space technology, road traffic technology and in the lighting industry.

“Through our own research & development at one location, we are able to produce quickly.” Markus Huber, graduate physicist

Made in Germany

Short communication and organisational paths as well as production depth have proven to be indispensable, especially for the development of such highly sensitive products.

State-of-the-art machine technology

The company’s ultra-precision machines are equipped with built-in vibration damping masses and operate in special air-conditioned rooms. In this way, the optical metal parts are produced with an accuracy of 0.1μ (equivalent to one ten-thousandth of a millimetre). Spherical and parabolic mirrors can be supplied for metalworking. Planar and polygonal mirrors (scanner mirrors) are also manufactured in individual and series production. Coatings in gold, silver or even infrared can additionally increase the reflection of the optics. Integrated fixings simplify the subsequent installation of the metal mirrors.

We find the right solution for every application! Hans-Erich Gubela, CEO

Free-form optics are one of the strengths of IMOS. The experienced physicists develop the perfect optics for every application in a customer-oriented manner. The IMOS production team then realises these in individual or series production. The quality assurance of each individual optic plays an important role. In this way, IMOS customers receive high-performance metal mirrors – optical components with particularly high precision.

Developments for the future

As a technology leader honoured by the state of Baden-Württemberg, IMOS supplies the optical components for numerous research projects. For example, precision optics installed in the DESIS hyperspectral earth observation system support DLR research projects on the ISS space station.